Generate Recurring Revenue With Labels, Tags

By Brian Albright, Business Solutions magazine

VARs can strengthen their customer relationships with ongoing label and consumable supply contracts.

When it comes to printer deployments, hardware sales occur every few years, but labels, tags, and other consumables can generate recurring revenue on a monthly basis. Not only will consumables keep cash flowing, the ongoing contact with the client can help ensure that they will maintain that relationship when it’s time to refresh the hardware.

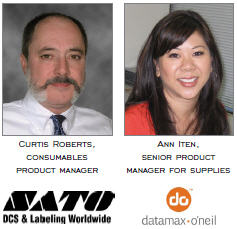

For VARs that want to enter the market or expand their consumables business, the first step is to get a clearer idea of what existing customers are actually using and how often they replenish. “It’s fine to ask where they purchase the consumables now and what they expect the consumables to do in their application,” says Curtis Roberts, consumables product manager at SATO America. “Knowing what your customers do and what they expect of their consumables will help to develop a supply strategy as the discovery process continues. Knowing your customers and their level of expectation will make it easier for you to find the correct materials supplier.”

Margins on consumables vary, so it’s important to adjust your own expectations when it comes to revenue based on how your customers are using their media. “Margins depend on size of the order and how regularly end users place orders,” says Ann Iten, senior product manager for supplies at Datamax-O’Neil. “Margins are higher with custom applications, such as specialized facestocks and adhesives. Margins also tend to be better on small-to-mediumsized applications as opposed to enterprise applications.”

Evaluating Labels And Tags

Not all labels are created equal; aftermarket providers often address one dimension of the sales equation (price), while OEMs focus on increasing throughput, minimizing the total cost of ownership of the printer, and optimizing up time. “Once all these variables are considered, up-front pricing becomes a smaller concern,” Iten says. “Regardless whether you are using an OEM supplier or an aftermarket supplier, a buyer should consider total costs.”

Also, if the customer expects high availability and fast shipments, then an ideal supplier may be one who is geographically close to that customer. Volume is another issue. If the supplier’s manufacturing capacity is limited, it may not be able to deliver the labels your customers need, when it needs them. “Some consumable suppliers also take extra care, work to high standards in manufacturing, use the best available materials, and have a reputation for quality,” Roberts says. “Some suppliers adhere to industrial standards like ISO compliance. If you are unsure about a supplier, see for yourself; request a site visit.”

RFID labels require even more due diligence. Suppliers should go through an intensive testing process with the printer being used in the application to ensure compatibility. In these deployments, customers are more concerned with accuracy and label location rather than speed and throughput, so pay close attention to those indicators.

“The printer needs to be able to read, encode, and verify,” says Iten. “If any of these steps fail, you should be able to mark the label as ‘VOID’ so that the user knows there was a problem and does not apply it to the product. Incorrectly encoded tags can cause mass confusion down the line.”

Expect Competition

Because customers that purchase large volumes of commodity consumables may be particularly price-sensitive, VARs just entering this space should expect a lot of competition. In some instances, other resellers will make unsolicited pitches to your existing client base.

Service levels will be a key differentiator. “I truly believe that the best defense of margins is being worth the money you are charging for your services and knowledge,” Roberts says. “Know your customer well, do a good job, and help them to achieve their business and financial goals. The relationship is still the best and most dependable defense.”

There is opportunity in offering additional services, such as specialized imprinting or inventory management. “You really do not have to own the inventory to help folks manage the counting and resupply,” Roberts says. “That could be a relief for some.”

Stay up to date with the products on the market by taking advantage of supplier training and webinars. Stay visible within the account, and maintain a thorough understanding of the application and how the supplies are performing.

“Adding the ability to provide consumables along with other values can fortify a VAR’s position and reputation with their customer,” Roberts says. “These are important services to the customer, and the VAR must invest in understanding the label application needs thoroughly.”